Textile Whitening Agent – Fluorescent Whitening Agent for polyester fibers and its blends

Chemical Nature : Styrylbenzene derivative, non-ionic.

Features

- Light Yellowish Liquid dispersion.

- Miscible in water in all proportions.

- Stable to oxidizing and reduction agents.

- Stable at all dilutions.

- Very less tendency to foam

Benefits

- Leomine Whitener HNI is a stable dispersion.

- High Yield Fluorescent Whitening agent.

- Desired effects achieved with addition at low dosage of Leomine Whitener HNI.

- Exhibits excellent whiteness. Slightly reddish tone.

- Exhibits good light fastness.

- Can be integrated in pre-treatment and finishing processes.

- Can be used for exhaust, padding and thermosol process.

- Suitable in resin finishing.

- Exhibits good re-dispersion property.

Ecology

This textile whitening agent does not contain APEO / NPEO

Storage

Leomine Whitener HNI has a shelf life of at least one year if stored in its tightly sealed original packing at temperatures between 5ºC and 35ºC in a dry place. Drums should be tightly resealed each time the material is taken from them, and their contents should be used up as soon as possible after they have been opened. Do not expose to direct sunlight.

Properties

Appearance: Light Yellow liquid

Solubility: Freely soluble in water

pH: Approx. 8

Ionicity : Non-ionic

Stability

Has tendency to dry on prolonged exposure to atmosphere but can be re-dispersed with addition of water and stirring.

Compatibility

This textile whitening agent is compatible with anionic, cationic and non-ionic auxiliaries.

Application

Leomine Whitener HNI should be thoroughly stirred before application

Recommended application recipes

HT Process:

- 0.1-0.5% Leomine Whitener HNI

- 0.5-1 g/1 Leomine Disperse XPD

- pH 4.5-5.5 (Acetic acid)

- Liquor ratio 1 : 5 to 1 : 20

- Initial temperature : 50-60ºC

- Heat up to 130ºC in 30 min

- 30-45 min at 130ºC

- The addition of Leomine Disperse XPD is particularly necessary in the fluorescent brightening of wound packages

Carrier Process:

- 0.1-0.5% Leomine Whitener HNI

… % carrier, as recommended by the manufacturer

- 0.5-1 g/l Leomine Disperse XPD

- pH 4.5-5.5 (Acetic acid)

- Liquor ratio : 1 : 10 to 1 : 20

- Temperature : 98-105ºC

- Time : 45-60 min

Thermosol process, two-stage drying and fixation:

- 0.5-5 g/l Leomine Whitener HNI

- Liquor pick-up : approx.60-70%

- Dry : approx. 120ºC

- Thermosol : 180-200ºC

- Time : 30-45 sec

The fixation conditions depend on the fabric construction. Tightly woven and relatively heavy qualities require longer fixation times or higher fixation temperatures than lightweight open materials. The padded and dried fabric should be protected from prolonged exposure to light because the unfixed fluorescent brightener is sensitive to light.

Single – stage drying and fixation

- In this procedure, the equipment used has a considerable influence on the fixation time and temperature. Empirical values are therefore more reliable than general recommendations.

- In case of doubt, it is advisable to carry out preliminary trials. The amount of Leomine Whitener HNI used is the same as in the two-stage drying and fixation process.

Curing step and resin finishing

- This textile whitening agent can also be fixed under the conditions that prevail in resin finishing and other finishing treatments.

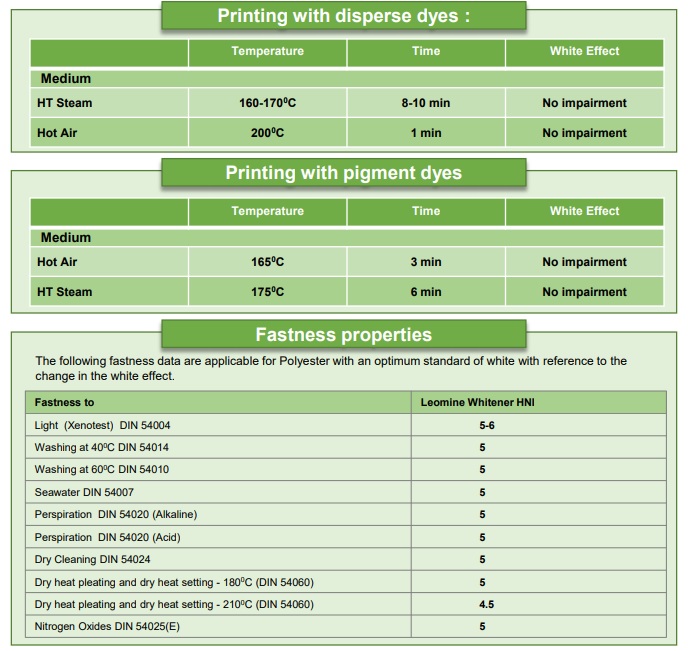

Fixation process for the fluorescent brightening of printed grounds

- The fluorescent brightening of printed grounds is frequently carried out in conjunction with the thermosol process.

- Knitgoods produced from texturized PES can also brightened by the HT process .

Safety

When using this textile whitening agent, the information and advice given in our Material Safety Data Sheet should be observed. Due attention should also be given to the precautions necessary for handling chemicals.

There are no reviews yet.